Looking for professional West Palm Beach dryer vent cleaning experts? We offer safe, code‑compliant airflow by implementing HEPA‑contained extraction, rotary brushing, and instrumented verification. You'll see reduced drying times, lower fire risk, and improved indoor air quality in our coastal humidity. We comprehensively evaluate run length, elbows, materials, and termination based on NFPA 211/IMC, then report pre/post CFM, static pressure, temperature rise, and photos. We repair crushed flex, secure joints with UL foil tape, and check damper function. See how we prove measurable improvements today.

Key Takeaways

- Licensed dryer vent experts working throughout West Palm Beach, enhancing safety from fires, air quality indoors, and energy performance per NFPA 211 and manufacturer specifications.

- Comprehensive cleaning: featuring HEPA negative-pressure capture, rotary brushing, termination hood cleaning, and UL-2158A certified repairs and sealing.

- Complete system analysis including airflow measurements, static pressure testing, temperature differential checks, and amperage monitoring; complete with before and after documentation and detailed test results.

- Quick action needed for warning signs: long drying times, hot appliance housings, musty aromas, weak exterior airflow, or activated thermal fuses.

- Seaside-specific options to combat moisture-related issues and corrosion concerns; providing complete service packages for residential properties, condominiums/HOAs, and commercial buildings.

Why Dryer Vent Cleaning is Essential in West Palm Beach

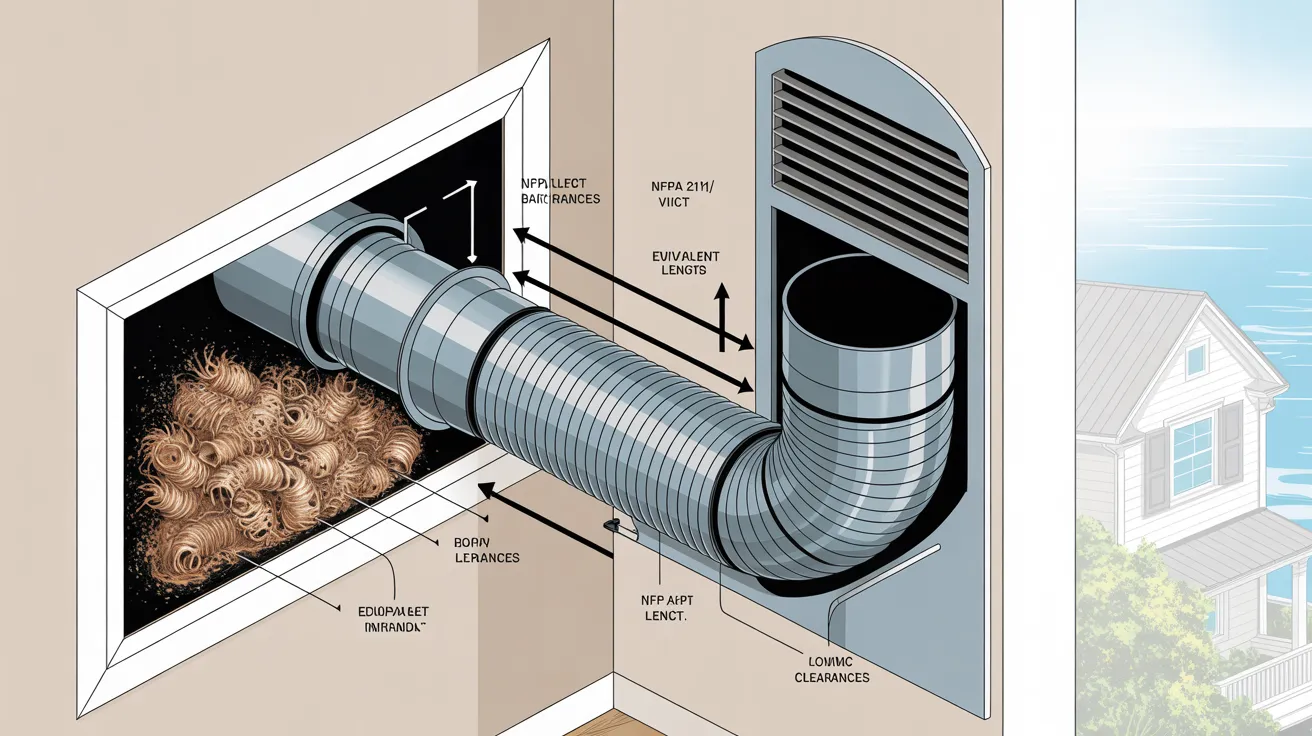

Because lint accumulation is a primary cause of residential fires, periodic dryer vent cleaning in West Palm Beach is an essential safety task that decreases fire risk, enhances airflow, and ensures equipment according to manufacturer and NFPA 211/CSA C22.1 guidance. You'll also shield wiring, terminations, and junction ducts from heat stress and excessive pressure. By removing obstructions, you reestablish design static pressure, enhance exhaust movement, and reduce cycle times, increasing energy efficiency and maximizing motor life.

In regions with coastal and high-humidity climates, maintaining appropriate humidity levels in your laundry area is crucial. Well-maintained vents effectively expel humid air, reducing the risk of moisture damage, mold development, and metal corrosion. Expert cleaning ensures correct duct installation requirements, including properly constructed metal walls, sealed connections, and adequate vent termination spacing, while checking accurate power and gas hookups and damper functionality. This guarantees safe, code-compliant operation throughout the year.

Warning Signs Your Dryer Vent Requires Immediate Service

If your dryer exhibits thermal stress, ventilation problems, or utility abnormalities, treat these as warning signs that require prompt intervention. If the unit's cabinet or door feels unusually hot, there might be a ventilation blockage. Prolonged drying times indicate diminished air movement and pressure concerns within the ventilation system. Unpleasant mustiness typically indicates dampness accumulation from insufficient airflow. Lint accumulation around the outdoor hood, backdraft damper stuck in position, or damaged flexible ducting all point to ventilation problems.

Look out for diminished exhaust stream at the outlet, an activated thermal fuse, or continuous switching on the high‑limit thermostat. Burn spots, shaking ducts, or noisy elbows suggest poor support or attachments. Should you detect the gas burner frequently switching or find erratic amperage, deactivate the unit and book a vent inspection.

Safety Benefits: Fire Protection and Air Quality

Even though a dryer might seem ordinary, its venting system poses a significant fire hazard when lint builds up or airflow becomes restricted. You minimize ignition hazards by maintaining proper duct dimensions, installing metal connectors, and installing regulation-compliant termination points. Adequate ventilation decreases temperature, enhances smoke prevention, and minimizes flammable lint deposits. Furthermore, you safeguard occupants from CO gas intrusion when gas dryers have unrestricted airflow and connections stay sealed.

Clean ducts significantly enhance indoor air quality. Optimal air filtration at the appliance and unobstructed exhaust facilitate allergen elimination by capturing debris, allergens, and particles rather than recirculating them. Managed exhaust enhances humidity regulation, minimizing mold pressure gradients and wall cavity condensation. Reduced cycles mean decreased thermal stress, extending fabric longevity. Adhering to NFPA 211/54 clearances and UL-listed components protects safety and efficiency.

Our Trusted Dryer Vent Cleaning Method

You start with a thorough inspection and code compliance check to locate duct damage, blockages, and terminal problems. Next, we conduct controlled lint and debris removal utilizing agitation techniques and negative-pressure systems to eliminate scattering. Lastly, we confirm outcomes using precise airflow testing and document that exhaust performance satisfies both manufacturer guidelines read more and local regulations.

Assessment and Inspection

Before commencing any maintenance, our technicians perform a detailed inspection and regulatory compliance check to document baseline conditions and detect potential hazards. We initiate with a visual inspection of the connection hose, vent path, termination hood, and distances to confirm UL-listed components, proper routing, and tight connections. We verify duct material, length, and equivalent elbows according to manufacturer specifications and Florida Building Code standards.

We measure static pressure, airflow, and backdraft damper functionality to flag potential restrictions or improper venting. We carry out moisture detection at the lint screen, coupling, and exterior vent to spot moisture problems or crushed ducts. We inspect proper ventilation, exhaust separation, and electrical connections. You'll get comprehensive reports, safety recommendations, and compliance guidance prior to additional work.

Debris and Lint Removal

After documenting baseline conditions, we move forward immediately into removing accumulated lint and debris using techniques tailored to your vent system's requirements. We begin by isolate power, secure the appliance, and install high-efficiency HEPA vacuum to ensure negative pressure. You'll see us deploy specialized rotating brushes or air-powered whips sized to the duct diameter, effectively removing compacted dryer lint and vent debris without damaging connections or flex ducting.

We begin from the termination point to the appliance, meticulously clearing elbows, seams, and junction connectors, then vacuuming with antistatic equipment to avoid re-contamination. We package and record the cleaned material for your records. We maintain the hood, bird screen, and damper, ensuring proper operation. Lastly, we inspect and secure mounting clamps, confirm screw tightness, and upgrade all nonconforming junction materials with UL-2158A certified components.

Testing and Verifying Airflow

Validate efficiency using instrumented airflow testing. Following debris removal, you should confirm system effectiveness by employing calibrated measurement tools including anemometers, manometers, and hygrometers. Set baseline metrics at the exterior outlet with the dryer connected and running on a timed cycle. Record duct static pressure, velocity, and volumetric flow. Compare these measurements against manufacturer specifications and ACCA/ASHRAE requirements to ensure safe performance.

Perform pressure measurements across key locations such as inline fittings, exterior hood, appliance collar, and connector hose. Locate unusual pressure drops that suggest remaining obstruction, crushed flex, or backdraft damper issues. Confirm that exhaust velocity successfully eliminates lint while remaining under code requirements for flex duct.

Log environmental conditions, including humidity and temperature to provide context for performance results. When targets are not achieved, implement suitable remedial steps. Conclude by attaching testing information to service records for future reference and compliance requirements.

Cutting-Edge Tools and Solutions We Implement

Though all homes are unique, we deploy a standardized toolkit to completely clean vents and adhere to code. You get a detailed approach that focuses on fire safety and airflow efficiency. We begin with robotic inspection to map the entire duct system, verify elbows, and identify constrictions without dismantling finishes. Following this, we implement thermal imaging to spot hidden heat anomalies indicating lint accumulation, crushed flex, or separated joints.

Our team employs rotary-brush shafts matched to duct diameter, then remove debris with HEPA-filtered negative pressure to prevent indoor re-entrainment. Where code permits, we deploy adaptable whip attachments for sensitive portions and nylon rods for solid metal sections. We track motor amperage, inspect backdraft damper performance, and seal joints applying UL-listed foil tape, rather than standard duct tape, delivering durable, code-compliant outcomes.

Professional Services for Residential and Commercial Properties

You receive tailored residential options that align with system requirements and component specifications while adhering to NFPA 211 and manufacturer guidelines. For multi-unit dwellings, we handle entry coordination, log results, and comply with HOA bylaws and local fire code to keep shared shafts and booster fans properly maintained. Businesses benefit from commercial-grade maintenance programs with regular cleaning, airflow monitoring, and comprehensive reports to fulfill OSHA standards and AHJ reviews.

Specialized Home Solutions

Engineered specifically for different living environments, our specialized residential dryer vent services tackle the unique compliance needs, ventilation requirements, and access challenges found in different types of residential buildings and multi-use developments. We initiate with an extensive assessment adhering to NFPA 211 and IRC standards, examining system components including ducts, elbows, termination points, and materials. Then, we clear lint and debris using specialized rotary brushing and HEPA-contained negative pressure to restore optimal airflow and pressure specifications.

We optimize energy efficiency by inspecting vent run geometry, addressing crushed flex, sealing joints with UL-listed foil tape, and adjusting proper backdraft damper tension. You'll get documentation: detailed reports showing before/after airflow, amperage, temperature differences, and photographic evidence. Given West Palm Beach humidity, we recommend seasonal scheduling ahead of peak dryer use, guaranteeing optimal safety, accelerated drying, and minimal system wear.

HOA Compliance Requirements

Due to multi-unit properties concentrate risk, our HOA compliance system aligns dryer vent services with key safety codes like NFPA 211, National Electric Code, and IRC/IMC, plus your bylaws and insurance requirements. We implement consistent service parameters, entry procedures, and record-keeping ensuring regulatory compliance with minimal resident disturbance.

We start with regulatory inspections of building vents and unit ductwork, assessing construction materials, duct length, endpoints, damper mechanisms, and air replacement. You'll receive safety-prioritized documentation, photographic proof, and improvement recommendations. Our experts clear obstructions, replace non-compliant flexible materials, secure junctions using approved materials, and establish maintenance schedules relative to building capacity and debris levels.

Our system timestamps every report, keep comprehensive unit activity logs, and deliver comprehensive service verification for insurance companies, governing boards, and inspection officials.

Commercial Maintenance Services

While fire risk escalates with lint buildup and runtime, our professional maintenance solutions implement dryer vent upkeep for houses, apartments, and commercial spaces under the same standards-based framework. You'll receive NFPA 211/54-aligned evaluations, ventilation testing, and recorded cleaning timeframes matched to facility use and occupancy levels.

We implement preventive maintenance contracts that specify maintenance schedules and response commitments, ensuring you avoid unexpected outages and violations. Our dedicated technicians examine proper duct materials, endpoints, and backdraft damper function, then measure system pressure and air speed to confirm system efficiency. We eliminate impediments, repair connections, adjust building stacks, and replace compromised flexible ducts with metal ducting when necessary.

You can expect detailed time-stamped documentation, pre and post readings, and intervention records-crucial evidence for insurance requirements, Authority Having Jurisdiction reviews, and committee reviews.

How Often to Schedule Dryer Vent Maintenance

It's advisable to plan professional dryer vent cleaning annually, or more frequently if usage is heavy (multiple loads daily), your vent run is long or has elbows, or you observe concerning indicators like longer drying cycles, excessive lint, or burning odors. In West Palm Beach's humid climate, lint typically will become damp, adhere to duct walls, and restrict air movement more rapidly, so be sure to follow annual maintenance guidelines. Plan maintenance according to use: quarterly for high-volume users or large homes; semiannual for average households; annual for occasional use.

Set up periodic maintenance reminders at the start of dryer season and hurricane season to evaluate air circulation, vent flap operation, and duct system reliability. Be sure to check external ventilation gaps, vent guard integrity, and ensure that airflow meets recommended CFM requirements and local building codes.

Transparent Pricing and What's Included

You've set your service interval; now understand the complete cost breakdown. We provide upfront estimates prior to starting, with scope defined by vent length, roof or wall termination, and access requirements. Our service includes mechanical cleaning processes, contained HEPA extraction, booster fan inspection, flow rate testing (pre/post CFM), and termination cap cleaning. Where required, we document bird barrier replacement and approved connector modifications.

Pick from our flat rate plans for standard single-run systems, or choose service packages combining lint alarm installation, cleaning, and airflow balancing. We record everything with static pressure measurements, photos, and NFPA 211/IMC compliance documentation. Our comprehensive invoices specify materials, labor, access charges, and applicable roof-safety fees. No hidden costs - additional work (rerouting, repairs, or remediation) demands your written approval before beginning.

Customer Reviews and Local Success Stories

Because results speak louder than promises, our customers report measurable improvements: improved drying efficiency, documented CFM gains, and static pressure restoration to code-compliant levels. In Customer testimonials, you'll see quantified outcomes: 30-50% reduction in cycle times, fans restored to factory specifications, and lint loads reduced to safe thresholds. You benefit from NFPA 211-compliant techniques, UL-certified parts, and documented airflow improvements.

Local milestones feature apartment complexes in West Palm Beach meeting HOA safety inspections after fixing crushed flex runs and faulty terminations. Safety inspections show significantly fewer dryer-fire hazards where we've corrected long-run friction losses and restored backdraft damper performance. We'll supply before/after meter measurements, documentation, and recommended intervals. This clear documentation helps you manage filter maintenance, manage energy usage, and maintain code compliance.

Questions and Answers

Do Your Technicians Have Licenses, Insurance, and Background Checks?

Indeed. You get licensed technicians who follow state and local codes, hold current certifications, and adhere to manufacturer specifications. Our company maintains full liability and workers' compensation insurance for your protection. We complete thorough background checks and ongoing safety training, including lockout/tagout, confined space awareness, and NFPA 211/IMC compliance. We document procedures, check clearances, and assess airflow and termination integrity. You can expect transparent reporting, controlled access for keys, and photo-verified results.

Do You Provide Emergency and Same-Day Dryer Vent Solutions?

Indeed, you can request urgent dryer vent cleaning. We prioritize life-safety hazards, clogged venting, and dryer overheating with urgent appointments and same day pickups. We provide a comprehensive inspection, performance checks, and vent maintenance to manufacturer specs. We inspect duct materials, correct vent exits, and required gaps, then document findings. You'll get complete inspection results, photos, and maintenance advice, with workmanship warrantied and final testing.

Can You Service Rooftop or Hard-To-Reach Exhaust Terminations?

Indeed, we handle rooftop or hard-to-reach exhaust terminations. You work with technicians trained for rooftop access, fall protection, and confined-space protocols. We deploy anchor points, ladder stabilizers, and OSHA safety protocols. We verify termination caps, backdraft dampers, bird guards, and spacing. We employ rotary brushing, HEPA vacuums, and camera inspections to guarantee full airflow. You'll get detailed compliance records, imaging, and performance data. When necessary, we replace damaged caps and secure penetrations to OEM standards.

Can Cleaning Void My Dryer's Manufacturer Warranty?

Professional dryer cleaning won't invalidate your manufacturer's warranty. For instance: with regular professional maintenance, your service professional clears accumulated lint, optimizes airflow, verifies temperature levels, and provides code-compliant documentation. Such records strengthen warranty coverage by showing responsible maintenance practices. Select licensed professionals who comply with NFPA 211 requirements and manufacturer guidelines, prevent unauthorized component removal, and maintain complete documentation through pictures and payment records. If existing damage is found, technicians will document it before servicing to protect your warranty coverage.

Are Before-And-After Airflow and Lint Volume Reports Available?

Indeed. You'll get documented airflow measurements and a lint collection analysis after service. We record pre- and post-cleaning CFM measurements (CFM) using professional measuring equipment and track static pressure changes. Regarding lint, we quantify mass and quantity, assess combustible buildup, and capture images of findings. Documentation covers vent path conditions, code-compliance observations, and safety recommendations. You'll receive clear, documented improvement data to help with maintenance planning and documentation for insurance and property management.

Final Overview

Your commitment to safety, efficiency, and code compliance matches ours - and so do we. Lint poses a serious fire hazard; the U.S. Fire Administration estimates nearly 2,900 dryer fires each year, with the bulk beginning in clogged vents. Imagine a vent packed like a felt blanket limiting airflow and overheating components. Regular maintenance will reduce fire risk, upgrade IAQ, and comply with manufacturer and NFPA 211 guidelines. Make sure to schedule regular service, document findings, and confirm airflow and termination. This will help protect your property, lower energy consumption, and keep your system stays within specifications.